Corrugated Cardboard: The most common material, chosen for its durability, insulation properties, and cost-effectiveness. Corrugated cardboard consists of a fluted layer between two flat liners, which provides strength and creates air pockets for insulation.

Kraft Paper: Often used as the outer or inner liner of the corrugated board, it offers a smooth surface for printing logos, brand names, or instructions.

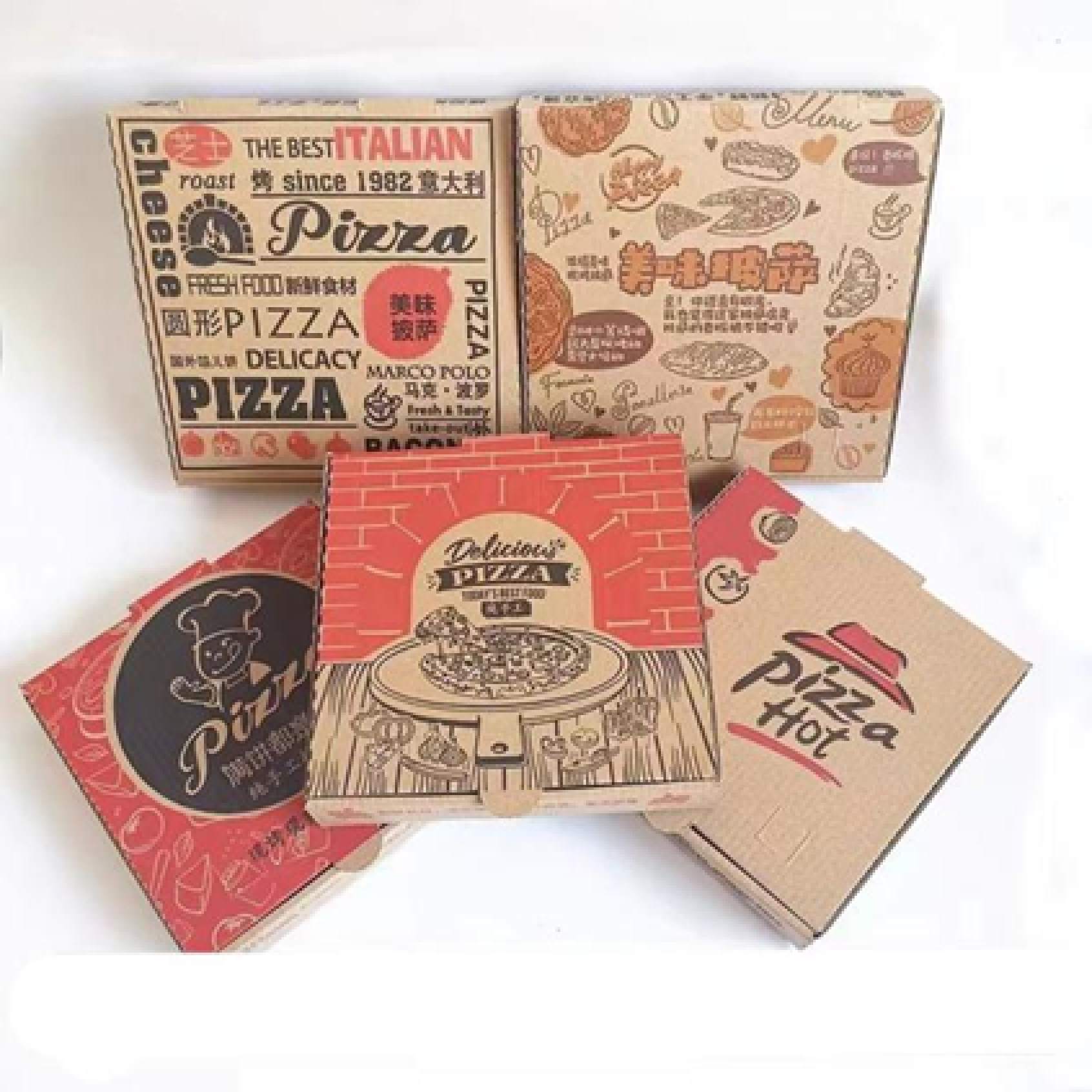

Shape: Typically square or rectangular to match the shape of most pizzas, with sizes varying (e.g., 10-inch, 12-inch, 14-inch) to fit different pizza diameters.

Base and Lid: The base holds the pizza, while the lid (attached via a hinge) closes securely to trap heat. Some lids have small vents to release excess moisture, preventing the crust from becoming soggy—this is a key design feature to balance heat retention and moisture control.

Flaps or Tabs: These help keep the lid closed during transport, ensuring the pizza doesn’t slide out. Some boxes have interlocking flaps for a tighter seal.

Heat Retention: The corrugated structure slows down heat loss, keeping the pizza warm for a longer period, which is essential for delivery services.

Protection: Shields the pizza from physical damage (e.g., crushing) during handling and transportation, preserving the shape of the crust and toppings.

Moisture Management: Vents (when present) reduce condensation inside the box, preventing the crust from getting soft. Without vents, trapped steam can make the pizza soggy, so the design often strikes a careful balance.

Branding: Serves as a marketing tool, with printed branding, contact information, or promotional messages to enhance brand recognition.

In summary, the pizza box is a practical and thoughtfully designed container that combines functionality (heat retention, protection) with practicality (transportability) and, increasingly, environmental awareness. Its design continues to evolve to meet the needs of both businesses and consumers.