In recent years, aluminum bottle caps are more and more widely used in our daily life, especially the packaging of wine, beverage and medical and health care products.

Aluminum bottle caps are simple in appearance and fine in production. Advanced printing technology can meet the effects of consistent color and exquisite patterns, bringing consumers an elegant visual experience; in addition, aluminum bottle caps also have good sealing performance, which can meet high Special requirements such as cooking and sterilization. Therefore, it has superior performance and is widely used.

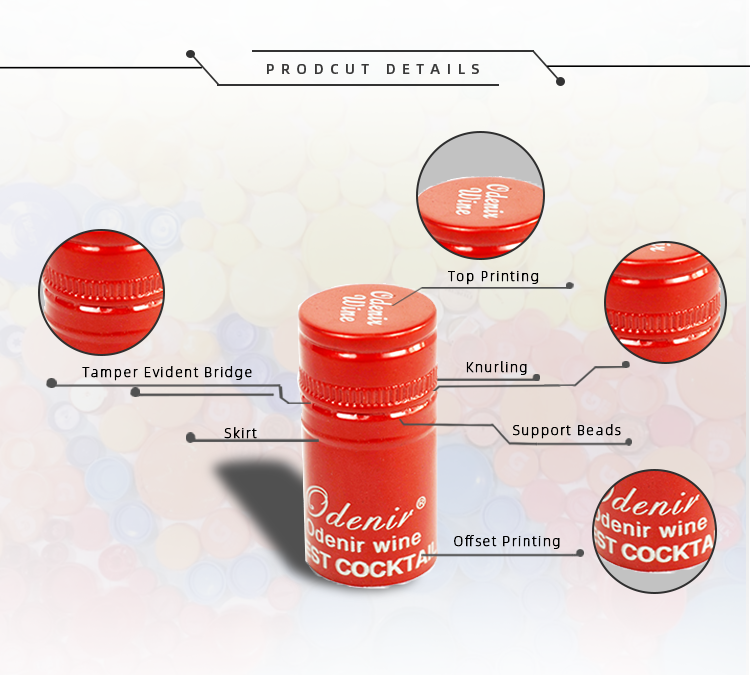

Taking out an aluminum bottle cap, we found that there are various patterns on its surface. These unremarkable designs are made through multiple production processes.

Aluminum bottle caps are mostly processed in production lines with a high degree of automation, so the requirements for the strength, elongation and dimensional deviation of the material are very strict, otherwise cracks or creases will occur during processing.

Material requirements: The surface of the bottle cap material is flat, without rolling marks, scratches and stains.

Common alloy state: 8011-H14, 3003-H16, etc.

Material specifications: the general thickness is 0.20mm-0.23mm, and the width is 449mm-796mm.

Production method: The production of aluminum bottle cap materials can be produced by hot rolling or continuous casting and rolling, and cold rolling. At present, the production plants of anti-theft cover materials in China mostly use continuous casting and rolling billets, which are better than casting and rolling billets.

With the innovation of technology, the functions and production forms of aluminum bottle caps are also developing in the direction of diversification and high-grade.

Therefore, in the future of wine bottle caps, we may foresee that aluminum bottle caps will still be the mainstream.

Post time: Jan-18-2022