In small or medium production runs, most bottle caps seem to perform “well enough.” Torque values stay within range, leakage complaints are rare, and the capping line feels stable. Problems usually start later, when volumes increase and line speed is pushed higher. At that point, issues that once felt marginal suddenly become visible: torque drift appears, batch-to-batch variation grows, and defect rates climb.

Why aluminum bottle caps perform better at scale is not a branding claim or a material cliche. It is the result of how aluminum behaves under repetitive mechanical load, how consistently it can be manufactured, and how it interacts with high-speed capping systems over long production cycles. For engineers and operations managers, the difference becomes obvious only when production pressure increases.

This article looks at the real reasons aluminum bottle caps tend to hold up better in scaled manufacturing, focusing on three problem areas that frequently trigger troubleshooting: torque drift, batch consistency, and the hidden side effects of higher line speed.

What “Perform Better at Scale” Actually Means in Capping Operations

Performance at scale does not mean a cap is stronger, shinier, or more premium. In production terms, it means predictable behavior across millions of cycles. A cap that performs well at scale delivers stable opening torque, maintains sealing integrity, and behaves consistently across batches, even when equipment speed and throughput increase.

In reality, many capping issues are not caused by dramatic failures. They come from small deviations that repeat thousands of times per hour. Slight deformation, minor friction changes, or inconsistent liner compression may be tolerable at low speed. At high speed, those same deviations compound.

Torque Drift: Why It Appears and Why Scale Makes It Worse

Understanding Torque Drift in Real Production

Torque drift refers to the gradual change in applied or retained torque during continuous operation. It often starts subtly. Early in a run, torque readings look fine. After hours of production, values creep upward or downward, sometimes crossing acceptable limits.

This drift is not usually caused by a single fault. It emerges from the interaction between cap material, capping head mechanics, friction at the bottle finish, and thermal or mechanical changes in the line.

Why High Line Speed Amplifies Torque Drift

As line speed increases, the system has less time to self-correct. Mechanical inertia becomes more pronounced, and any variability in cap geometry or material response shows up faster. At higher speeds, capping heads rely on repeatability rather than adjustment. If caps deform inconsistently or friction fluctuates, torque drift accelerates.

Aluminum bottle caps tend to behave more predictably under these conditions because their elastic response is stable. When compressed and released repeatedly, aluminum returns closer to its original shape than many alternative materials. This reduces cumulative deformation that would otherwise alter torque behavior over time.

Batch Consistency: Why It Matters More Than Most Teams Expect

Batch Variation as a Hidden Production Risk

Batch consistency is often discussed as a quality metric, but its operational impact is sometimes underestimated. In high-speed production, even small differences between cap batches can disrupt torque control. If one batch requires slightly more force to form or seal, the capping system may compensate in ways that affect subsequent bottles.

When batches vary, torque distribution widens. That means more bottles near the upper and lower limits, increasing the risk of leakage, over-tightening, or consumer complaints.

Material Uniformity and Aluminum Caps

Aluminum bottle caps benefit from tightly controlled alloy composition and forming processes. This leads to uniform wall thickness, predictable hardness, and consistent interaction with liners. In practice, this translates to narrower torque distribution curves across batches.

For production teams, this consistency reduces the need for frequent recalibration. It also allows higher confidence when increasing line speed, because the cap behavior remains stable across long runs and multiple shipments.

What Really Happens When Line Speed Goes Up

Mechanical Lag and Control Limits

Increasing line speed changes the dynamics of the entire capping system. Sensors, actuators, and feedback loops must respond faster. Any delay between detection and correction becomes more costly. When cap behavior is inconsistent, the control system struggles to keep up.

This is where many problems surface. Torque settings that worked at moderate speed no longer hold. Variability that once averaged out now appears bottle by bottle.

Cumulative Effects Over Long Production Runs

High-speed lines magnify cumulative effects. Minor wear on tooling, slight temperature increases, and gradual lubrication changes all interact with cap material behavior. Caps that deform unevenly or recover slowly contribute to widening torque variation over time.

Aluminum bottle caps, by maintaining dimensional stability under repeated stress, reduce this cumulative drift. That does not eliminate the need for maintenance, but it slows the rate at which problems emerge.

Practical Measures to Control Torque and Consistency at Scale

Monitoring Beyond Initial Calibration

One common mistake is relying solely on initial torque calibration. At scale, real-time or periodic monitoring becomes more valuable. Tracking torque trends across a shift can reveal early signs of drift before defects spike.

Stable cap behavior makes these trends easier to interpret. When material variability is low, changes in torque are more likely to reflect equipment or process issues rather than random cap behavior.

Cap Geometry, Liner Interaction, and Repeatability

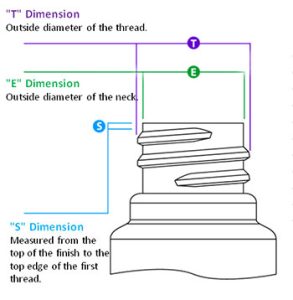

Cap geometry and liner selection play a major role in torque stability. Aluminum caps support precise forming, which helps maintain consistent thread engagement and liner compression. This repeatability becomes critical when line speed increases and margins tighten.

When Aluminum Is Not Automatically the Best Choice

It is important to be clear: aluminum bottle caps are not the answer to every packaging scenario. Certain products, environments, or cost constraints may favor alternative materials. In highly corrosive conditions or applications with extreme weight sensitivity, different solutions may be appropriate.

However, when production scale, speed, and consistency are the primary concerns, aluminum’s mechanical stability offers clear advantages.

Scale, Quality, and the Cost of Instability

Defects caused by torque drift or batch inconsistency are rarely free. They show up as rework, line stoppages, customer complaints, or brand damage. At scale, even a small defect rate becomes expensive.

Choosing a cap solution that behaves predictably under pressure reduces these hidden costs. For many producers, the question is not whether aluminum caps cost slightly more per unit, but whether they reduce operational risk when output increases.

About Yantai Original

Yantai Original is a packaging solution provider specializing in aluminum bottle caps, glass bottles, and coordinated secondary packaging. With a focus on export markets and scalable production, the company supports brands ranging from small batches to high-volume operations. Its manufacturing systems emphasize batch consistency, torque stability, and fit verification, helping production teams maintain control as line speed and output grow.

Conclusion

Scale exposes weaknesses. What works at low speed often fails quietly when production accelerates. Torque drift, batch variation, and line speed side effects are not isolated problems; they are connected symptoms of system behavior under stress.

Understanding why aluminum bottle caps perform better at scale requires looking beyond surface features and into material response, process consistency, and mechanical interaction. When these factors are aligned, scaling up becomes a controlled step forward rather than a gamble.

FAQs

Why do aluminum bottle caps show less torque drift at high line speed?

Because aluminum maintains stable elastic behavior under repeated compression, reducing cumulative deformation that contributes to torque drift during long, high-speed runs.

How does batch consistency affect torque control in large production volumes?

Consistent batches keep torque distribution narrow, making it easier for capping systems to maintain control without frequent recalibration.

Why do more problems appear after increasing line speed?

Higher speed amplifies mechanical lag, wear, and material variability. Small deviations that were insignificant at lower speed become visible and costly.

Are aluminum bottle caps always better for every application?

Not always. Material choice should consider product type, environment, and production priorities. Aluminum performs especially well when consistency and throughput are critical.

What practical steps help maintain torque stability at scale?

Regular torque trend monitoring, controlled batch sourcing, precise cap geometry, and proper liner selection all contribute to stable performance in high-volume production.